Real-Time Component Analysis at up to 600 Samples Per Hour

Measures: fat, protein, lactose and more

The Bentley FTS represents the latest in state-of-the-art technology for automated milk analysis at 600 samples per hour. Engineered in accordance with Bentley Instruments’ rigorous design principles, it provides precise and accurate measurements. The Bentley FTS uses the Fourier Transform Spectrometer (FTIR) to measure the milk composition, including fat, protein and lactose. After first being stirred, the milk is drawn from a sample vial and delivered to the measurement module. The sampling, sequencing and identification of the sample vials are functions performed by the Autosampler.

Fully integrated software controls

With this advanced instrument, control of the FTS module is integrated into a single Windows-based software program. The simple and intuitive graphical user interface is designed for easy operator use. The software’s sophisticated data export/reporting functions and network access capability allow laboratory supervisors to monitor instrument status and analyze results remotely.

Technology summary

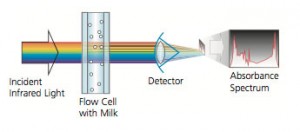

The Bentley FTS component analyzer uses an industrial Fourier Transform Spectrometer (FTIR) that captures the complete infrared absorption spectrum of the milk sample for component analysis. Collecting the complete spectrum allows the calibration to be based on all spectral characteristics of each particular component. The infrared spectrum may be permanently stored so that other calibrations may be retroactively applied to your data at any time in the future.

Testing standards

The Bentley FTS exceeds the IDF 141C:2000 and ICAR requirements for component measurement employing AOAC approved methodology.

Technical overview of the Bentley FTS module

Technical overview of the Bentley FTS module

The Bentley FTS contains a Fourier Transform Spectrometer (FTIR). The optical deck of the FTS is housed in a hermetically-sealed enclosure, ensuring enhanced temperature stability and environmental robustness. The air in the sealed deck is pumped out, leaving the deck under vacuum. The combination of the hermetic seal and removing the humid air greatly reduces the humidity load on the enclosed desiccant, virtually eliminating the preventative maintenance task of frequent desiccant regeneration.

Remote diagnostic capabilities

The web-enabled diagnostic features of the Bentley FTS model allow Bentley Instruments to access your machine from any location. This enables your laboratory personnel and Bentley Instruments to collaborate and analyze all system functionality, no matter where the instrument is located.

Other Bentley FTS features

(click image to view)